10 Landmark Achievements

10 Landmark Achievements

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

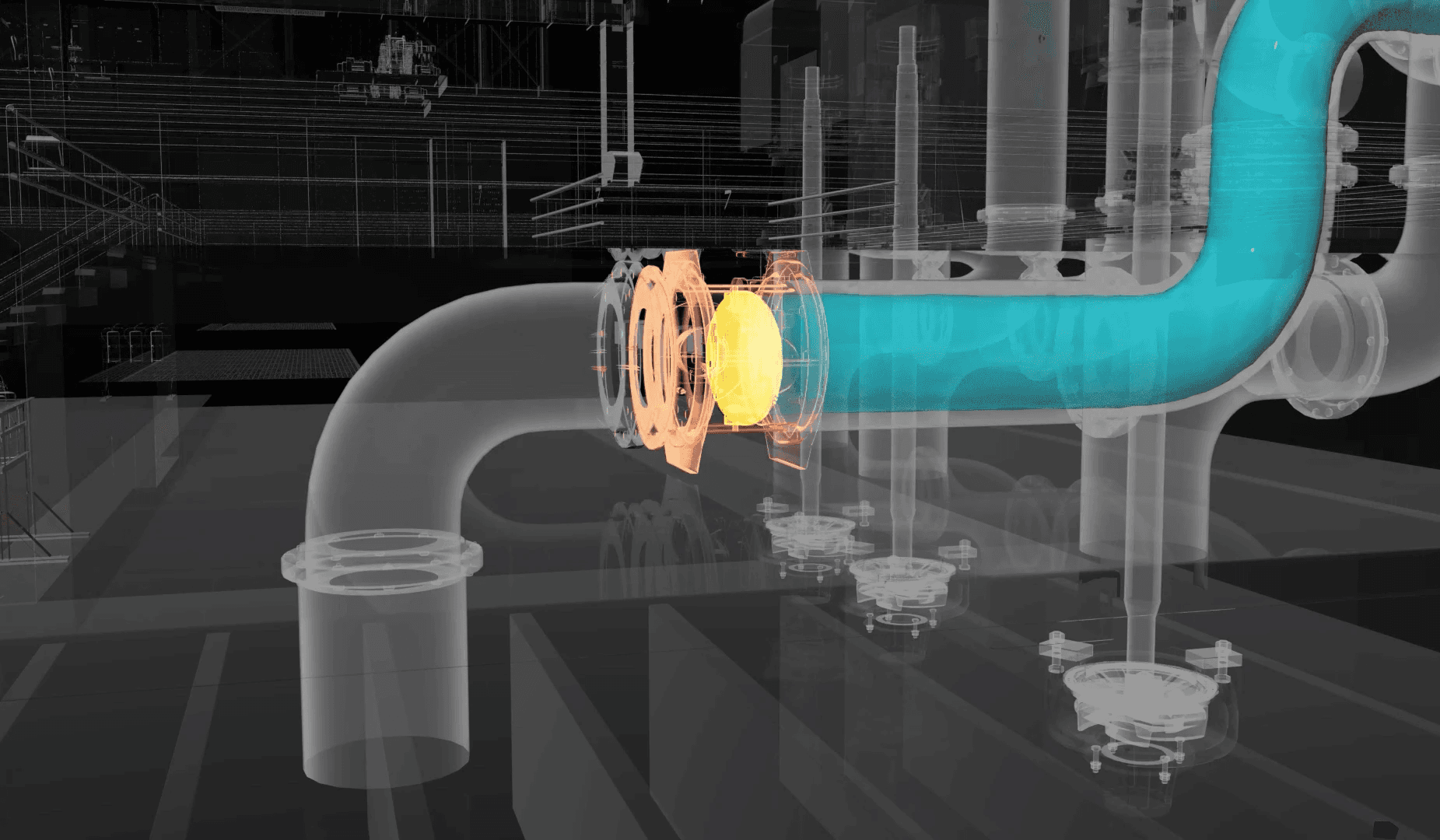

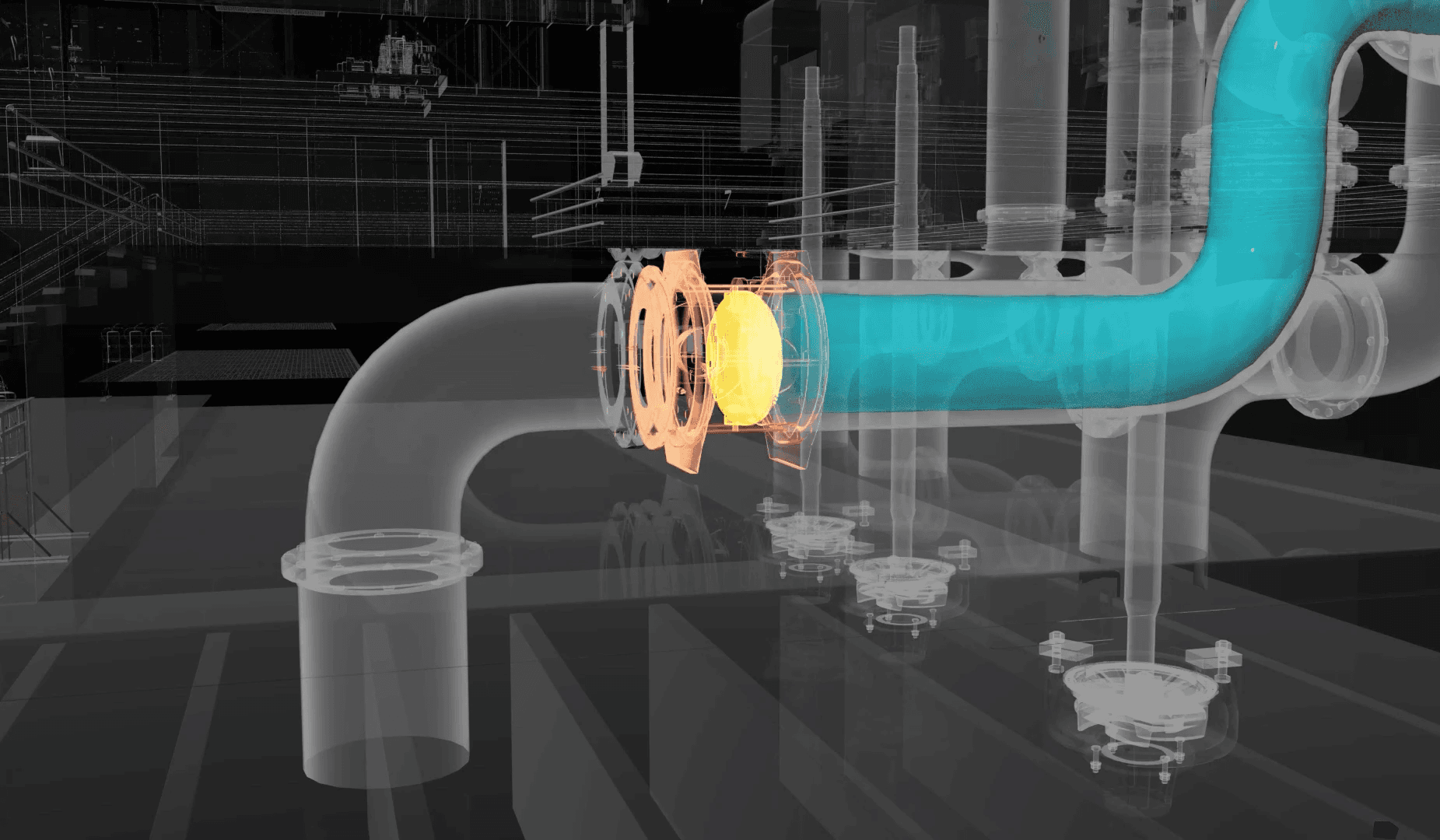

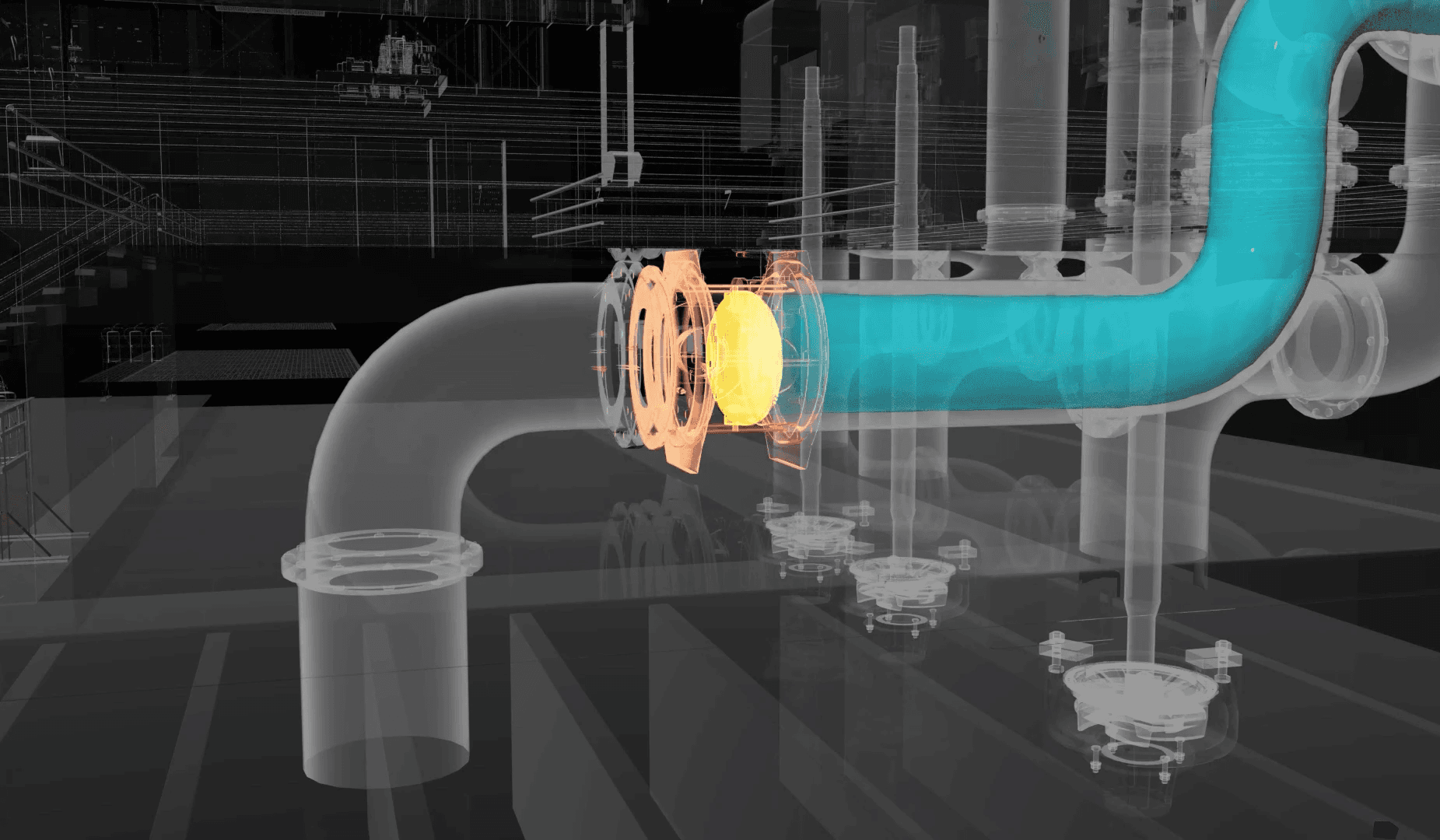

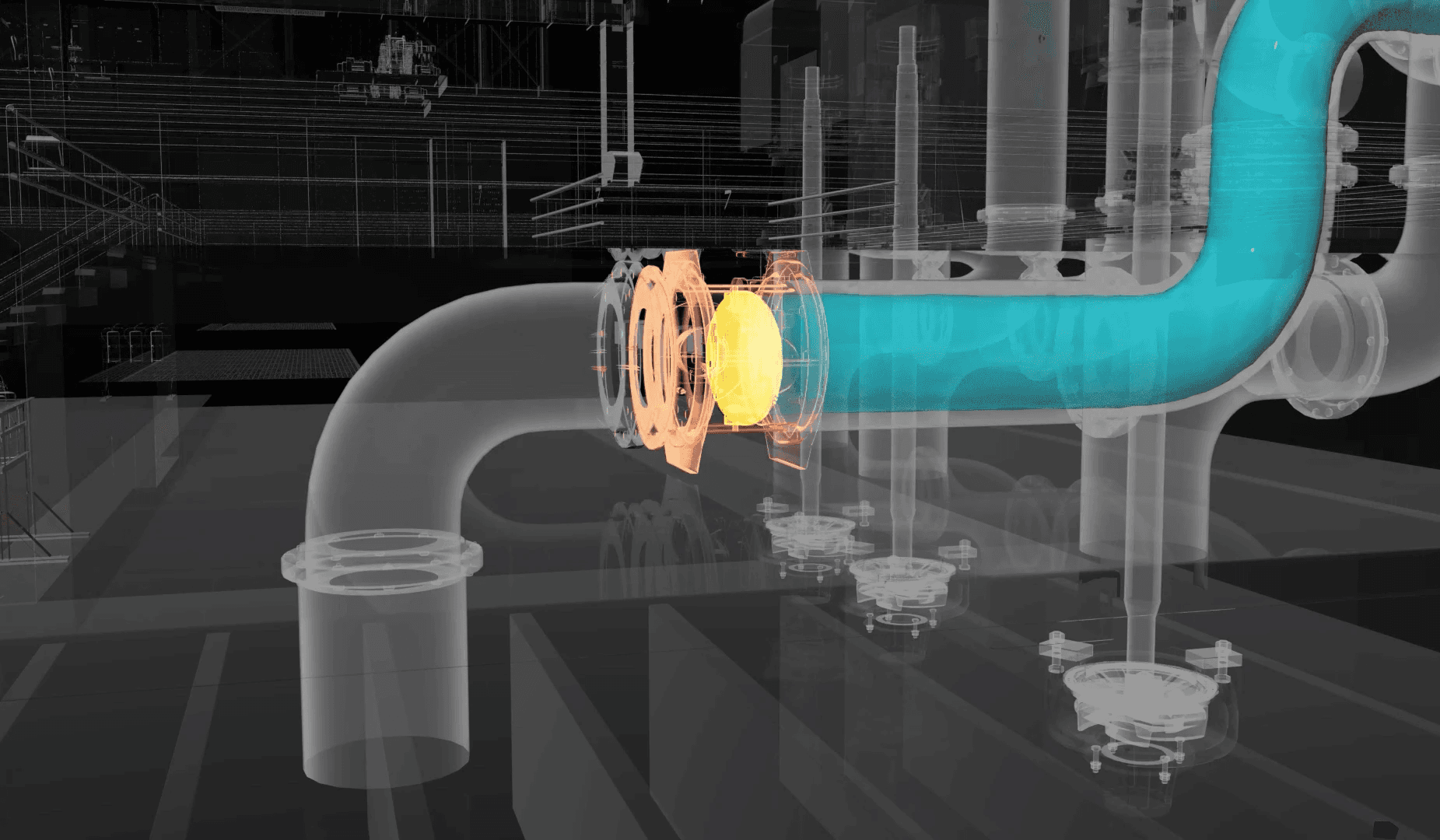

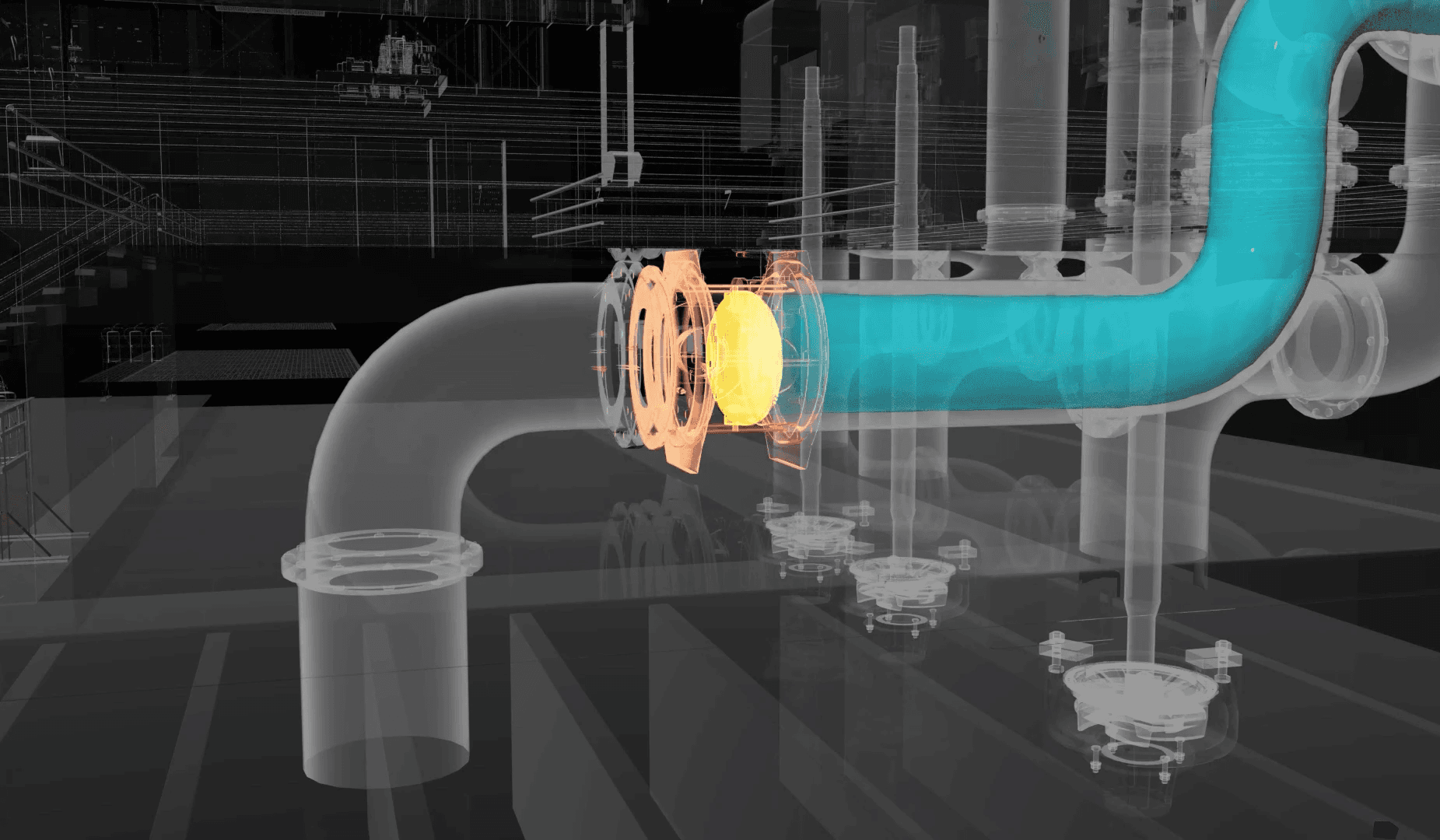

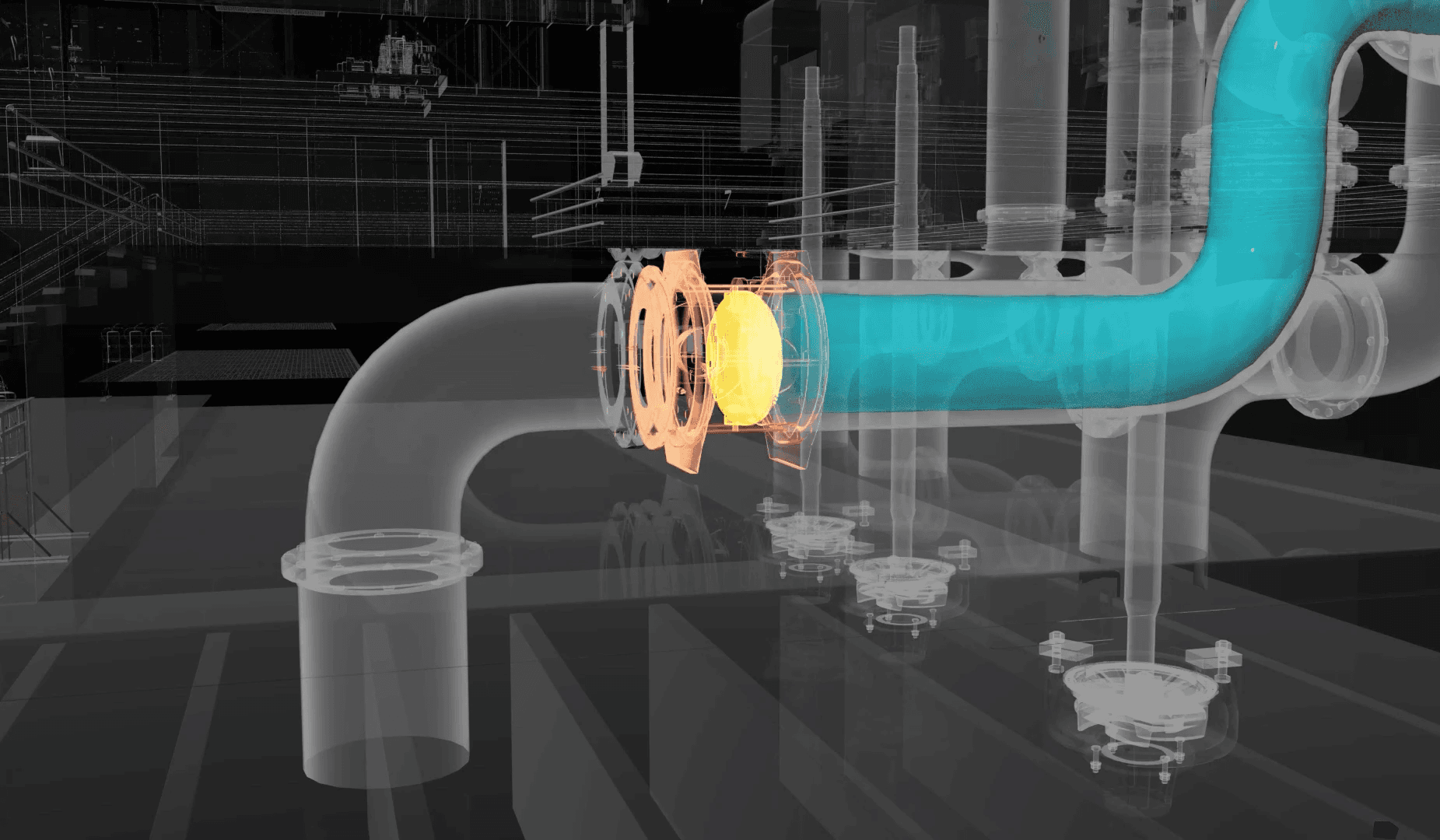

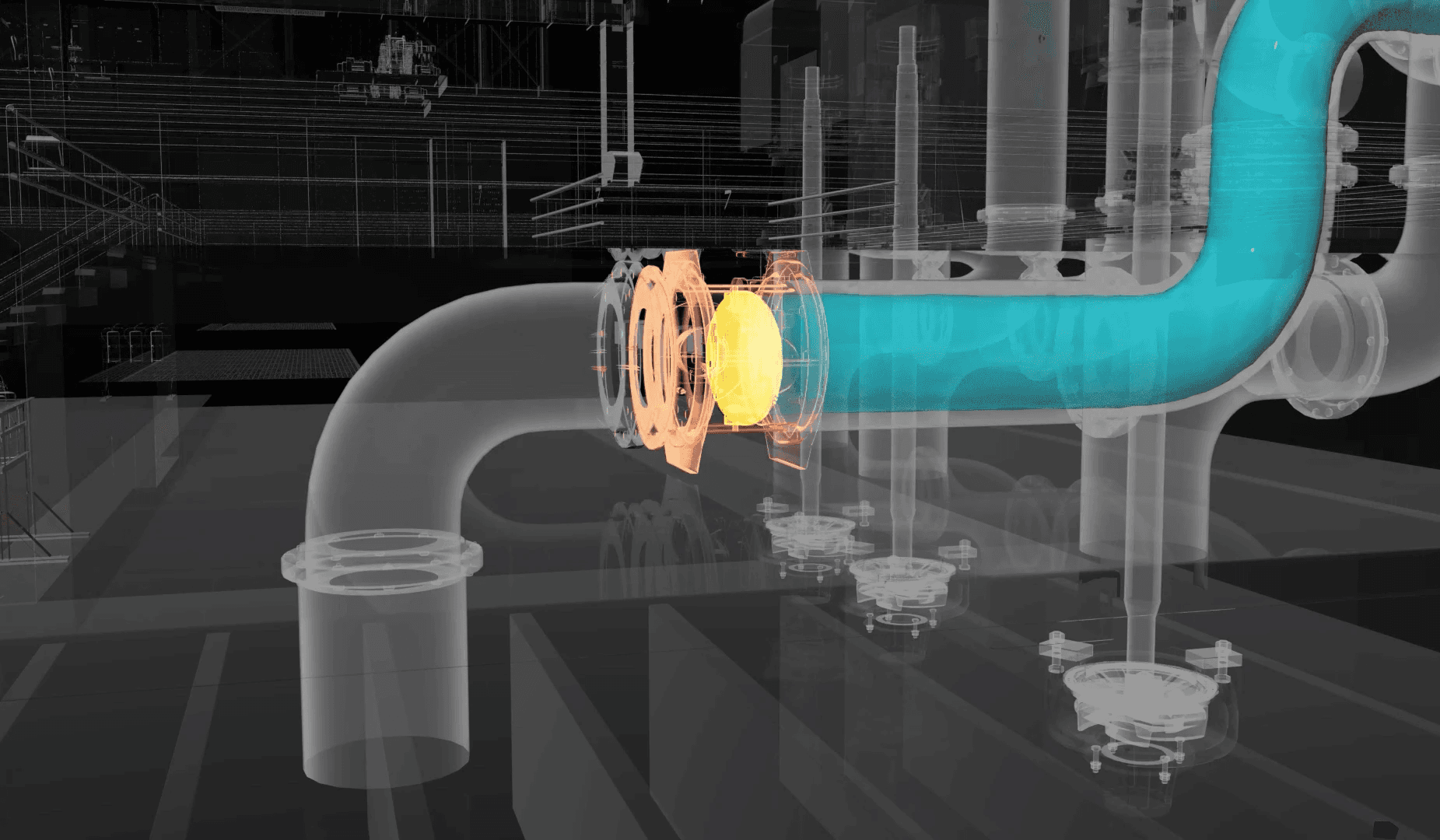

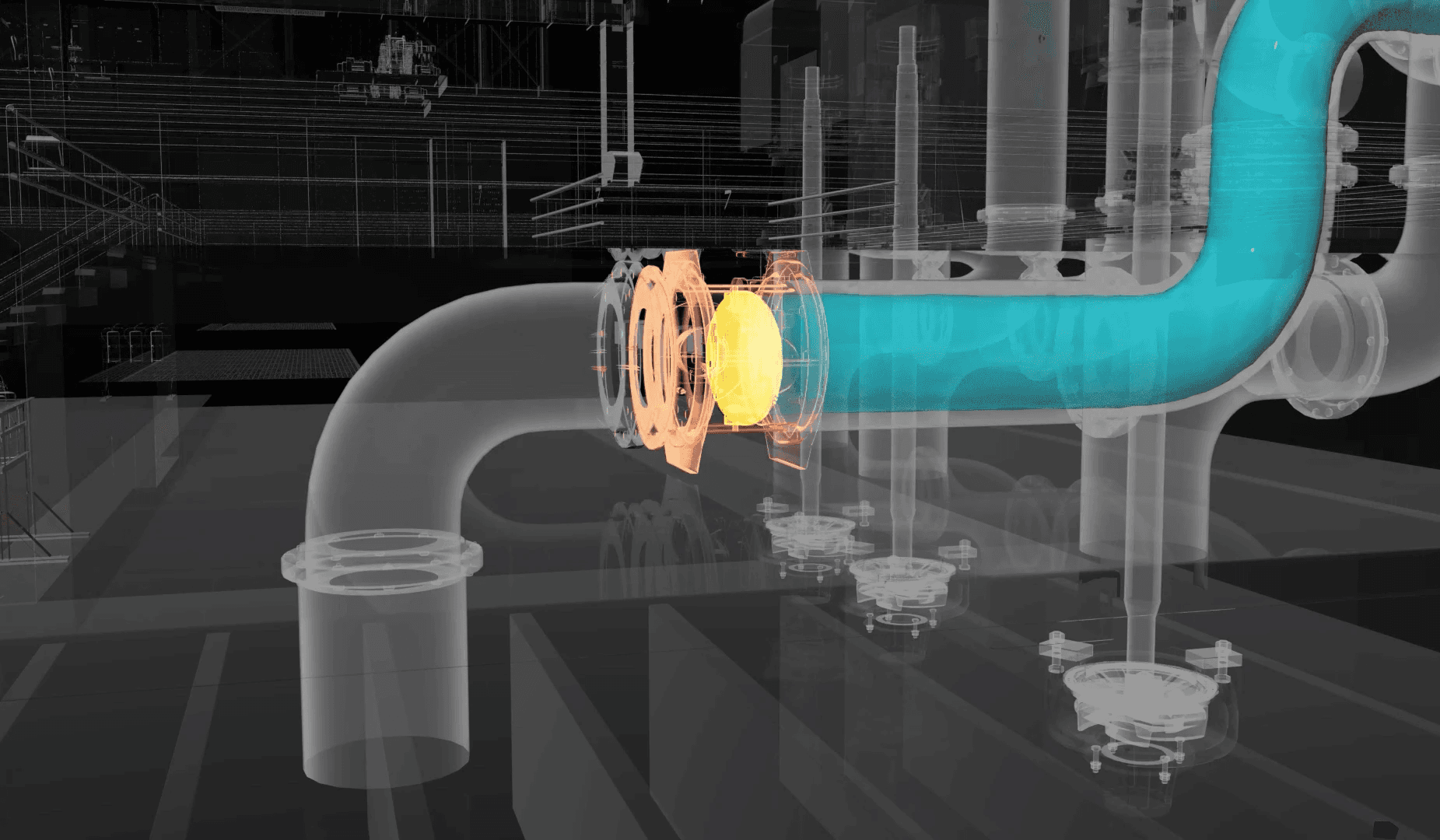

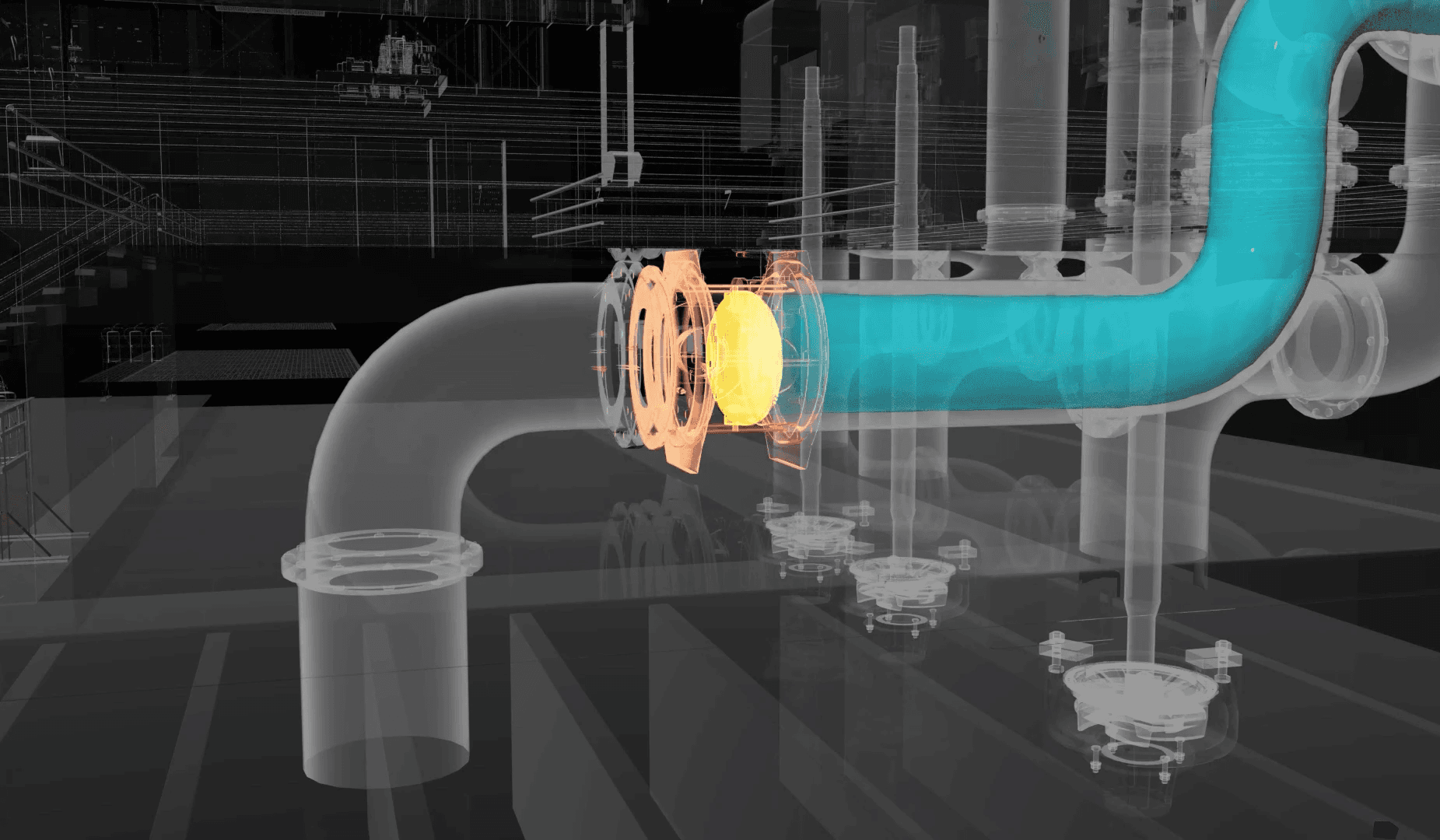

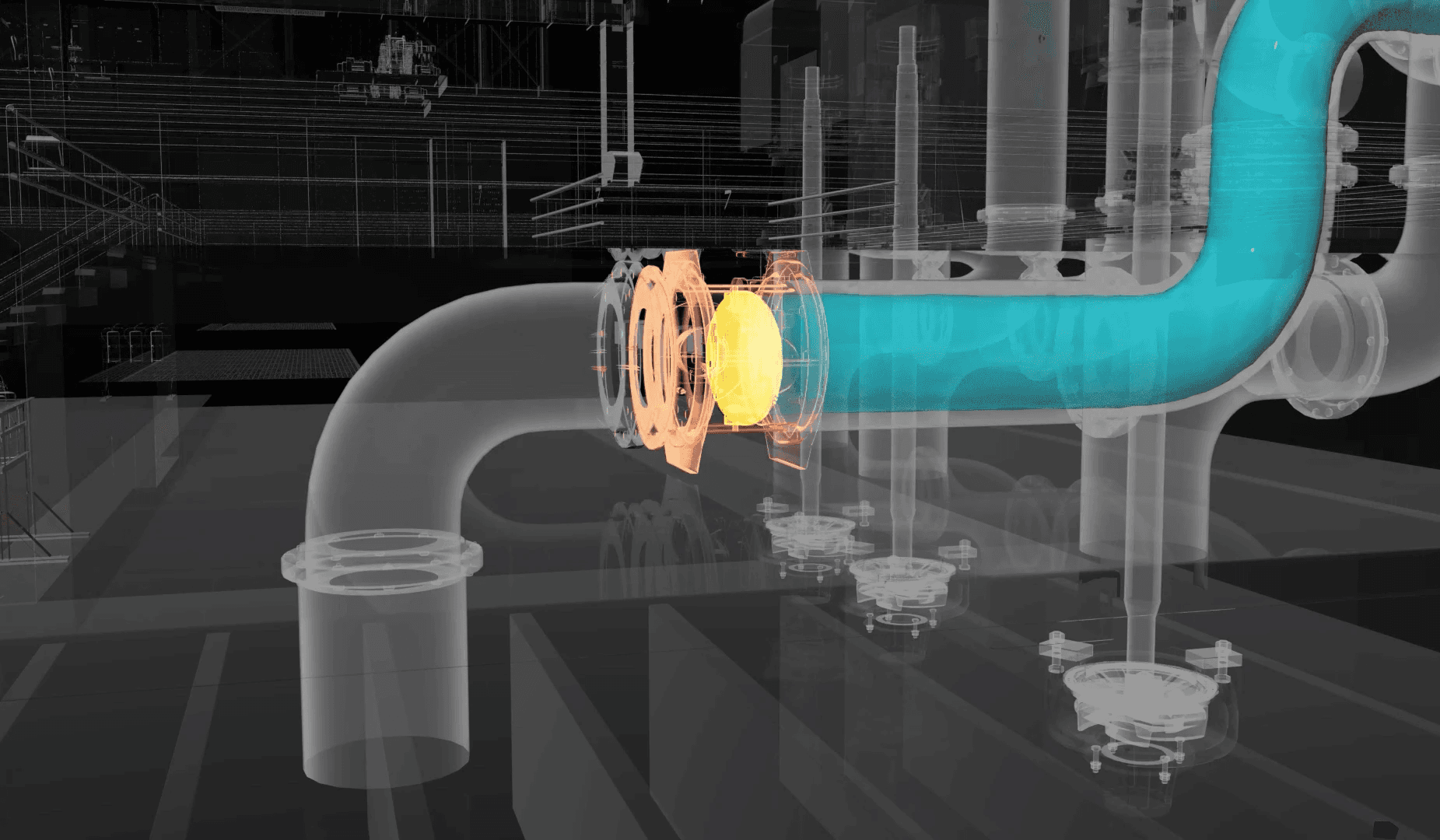

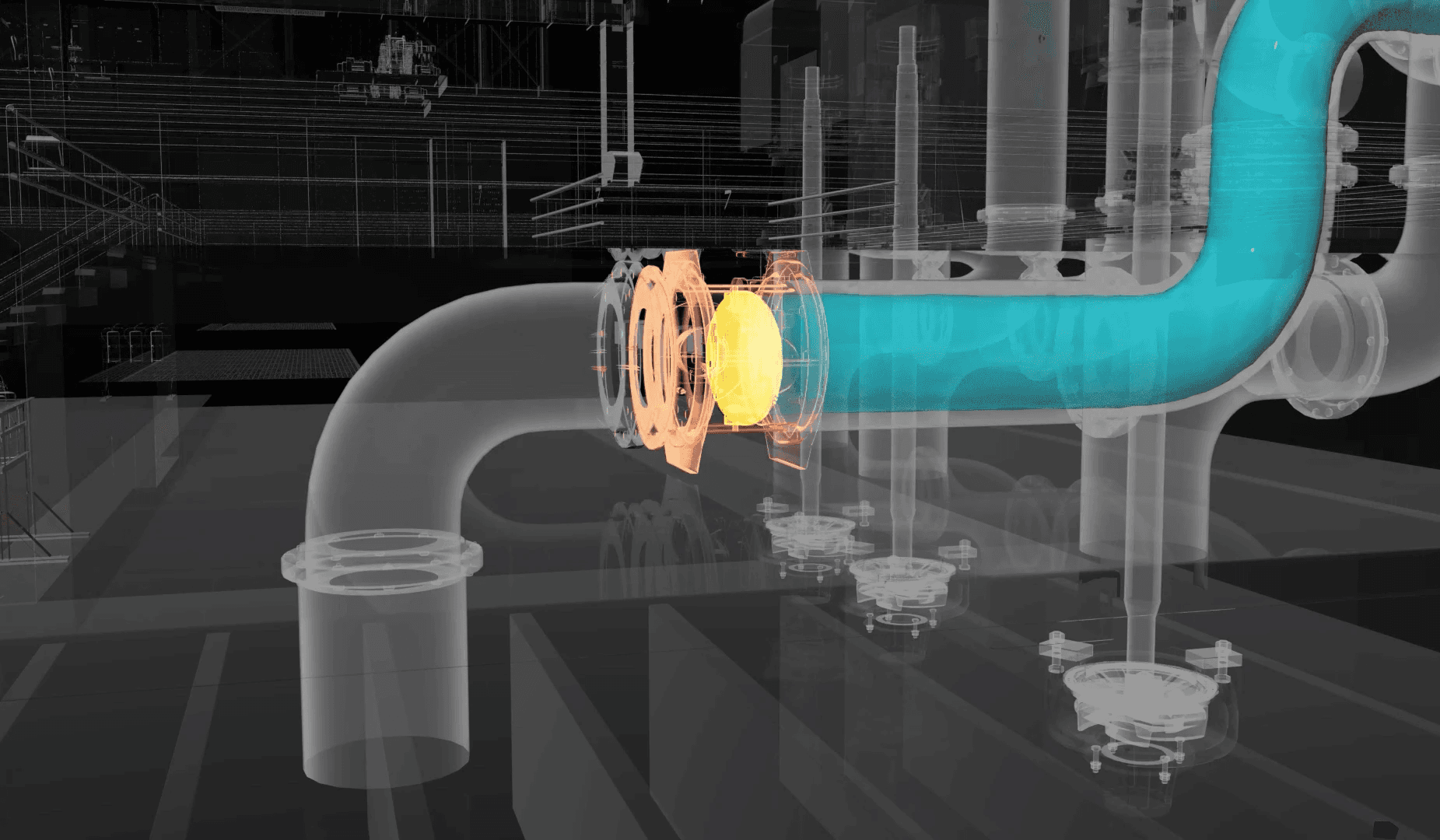

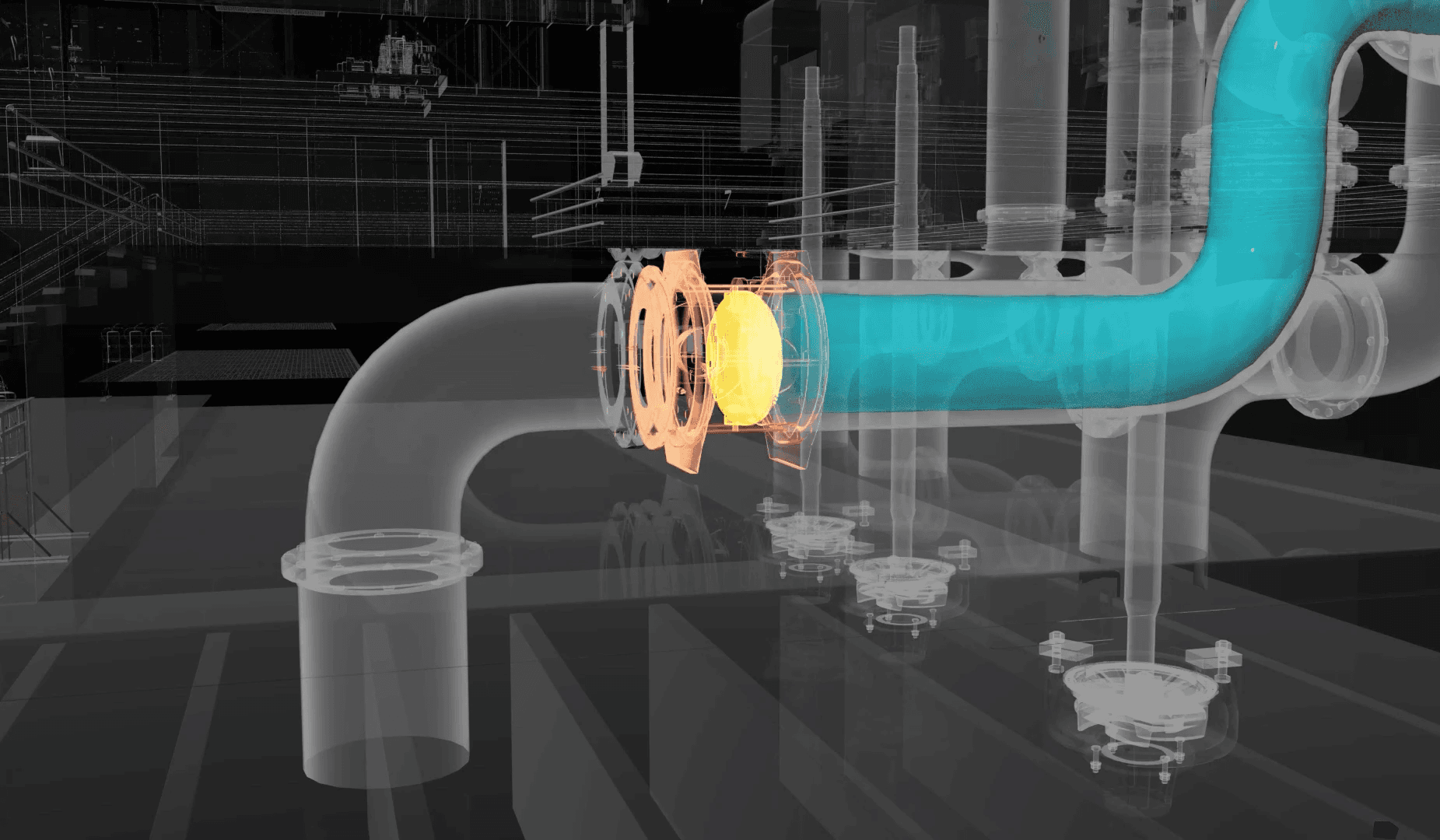

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.

Pioneer

Pioneer to introduce the step-In and Step-Out procedure of Varuna, Surya & Matsya Flap-gate associated with CE (Navy).

Pioneer

Pioneer to introduction bevel gear system for optimum and safe operation of 1800mm B.F Valves.

Pioneer

Pioneer to execute challenging underwater works, changing of pedestals with foundation bolts without constructing coffer-dam.

Pioneer

Pioneer to recover/retrieve submarine canopy toppled in underwater at shipbuilding center .

Pioneer

Pioneer to recover/retrieve flap-gate of naval dockyard weighing 360 ton (44mtrsX16MtrsX4Mtrs) submerged in the silt under (-) 14MRL . Introducing new emergency recovery techniques .

Pioneer

Pioneer and introduced customized repairing methodology of GRP panels on Submarine in Afloat condition underwater , saving down time and docking expenses to Indian Navy .

Pioneer

Pioneer to manufacturing and supply of mulching machine to NTPC for dyes spread around thousands of acres of land to avoid environmental pollution.

Pioneer

Introduced and executed De-silting of Sub-Marine in afloat phase with custom made pump and underwater support systems in constrained spaces not exceeding 300 mm having only one entry and exit point.

Pioneer

Execution of fabrication and installation of innovative custom built manifolds for various naval ships at Naval dockyard.

Pioneer

First in execution of technically challenging automation for the whole docking and undocking operations with under water equipment’s, Real time sensors , VFD driven winch and SCADA monitoring systems.